Technical data

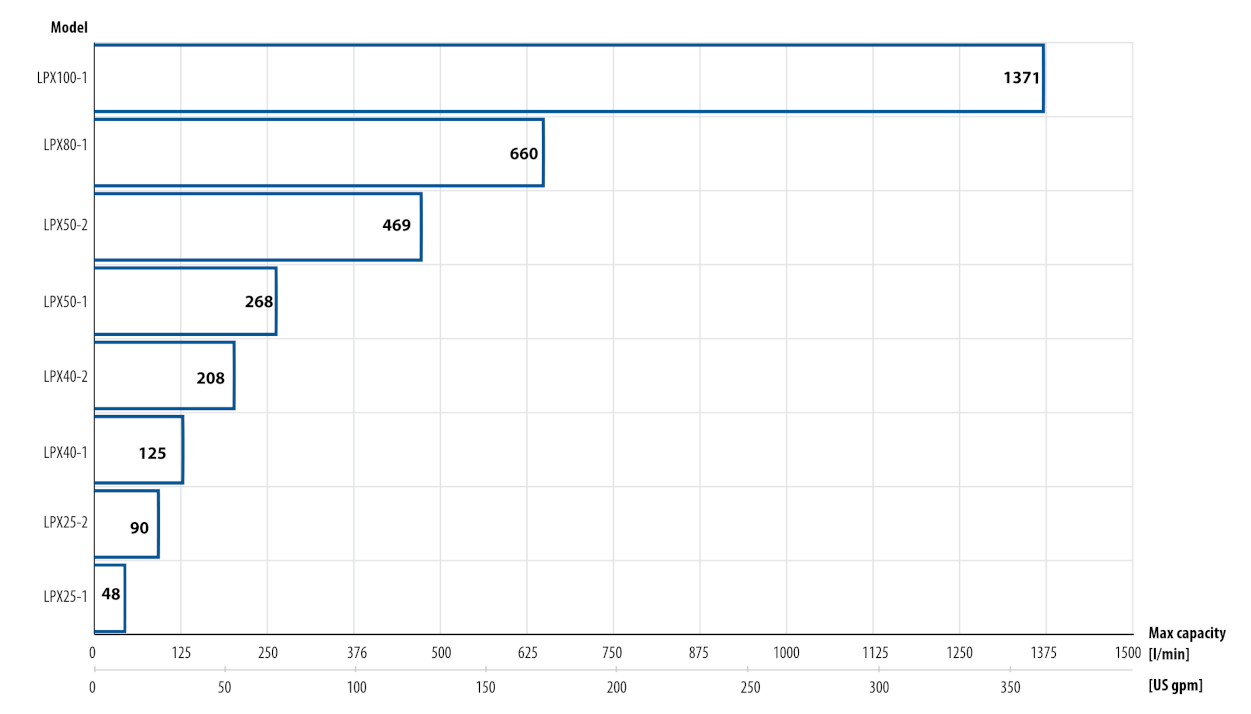

| Capacity: | Qmax. = 1371 l/min Qmax. = 2,29 l/rev |

|

| Max. speed | 1200 rpm | |

| Max. operating pressure: | PN10 | |

| Max. particle size: | 3-15 mm particle sizes depend on the pump model |

|

| Max temperature: | 100 °C | |

| Rotor type: | lobe, made of AISI 316L | |

| Casing and cover material: | 316L stainless steel | |

| Mechanical seal material: | SiC/SiC | |

TYPICAL APPLICATIONS

| Industry | Example of application |

|

Bakery products |

Cakes, flavors, frostings, fruit fillings, fats and oils, sweeteners, yeast starters. |

|

Beverage production |

Beer, wort, yeast, soft drinks, fruit concentrates, fruit drinks. |

|

Canned goods |

Baby food, soups, stews, tomato or fruit puree, vegetables, diced vegetables, baby paps, puddings, jams, jellies, salad dressings, mayonnaise. |

|

Confectionery products |

Syrups, cream fillings, chocolate. |

|

Cosmetics |

Face creams and lotions, hair styling gels and fluids, essential oils, dyes and alcohols. |

|

Dairy |

Cream, milk, curd and whey, yogurts. |

|

Meat production |

Meat emulsions, ground meats, pet foods, animal fats. |

|

Pharmaceutical industry |

Pills masses, syrups, extracts, emulsions, suspensions. |

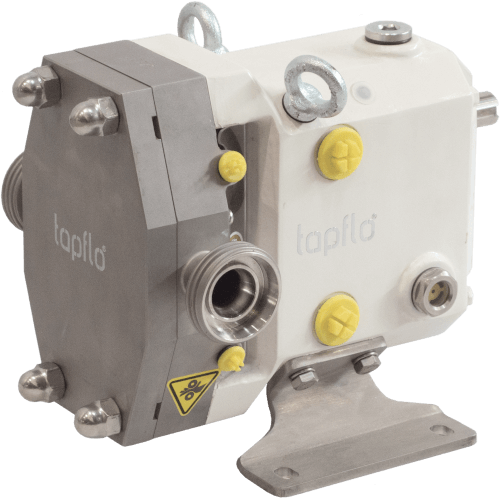

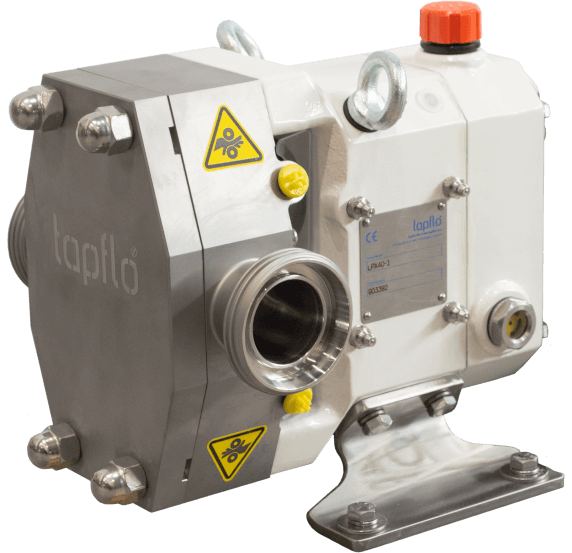

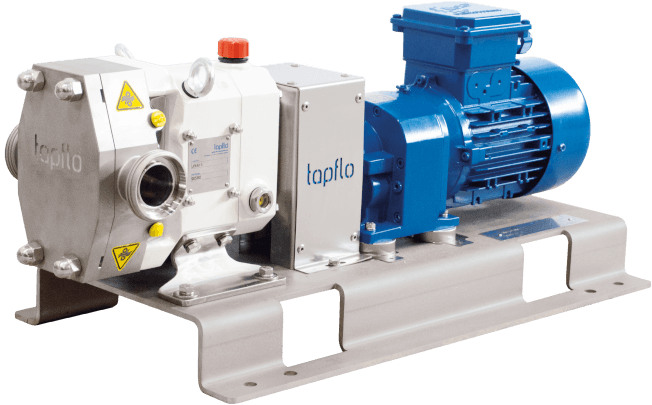

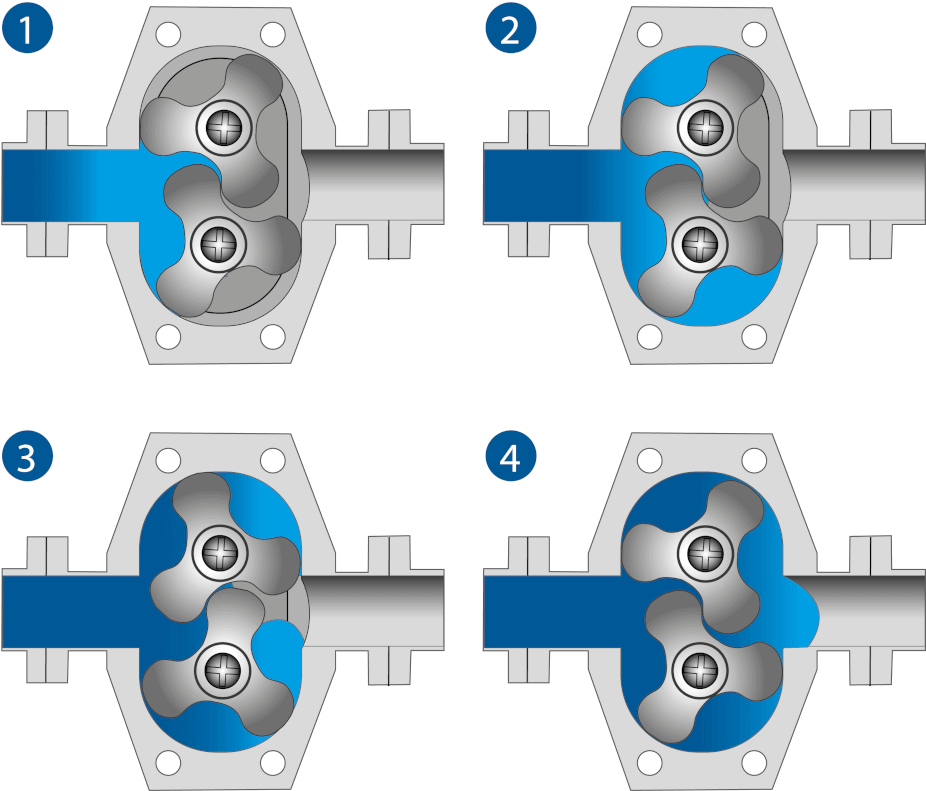

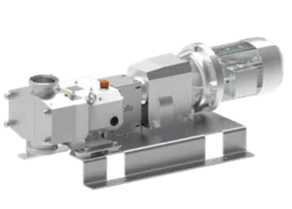

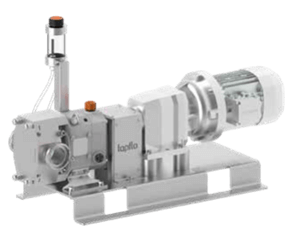

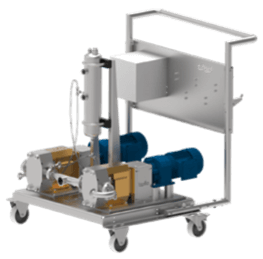

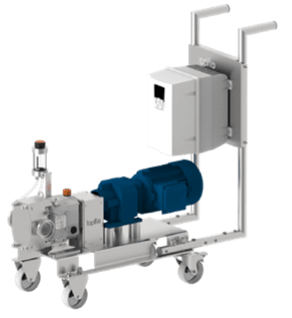

LPX series pumps are hygienic rotary lobe pumps characterized by low shear forces and gentle pumping of both high and low viscosity products. The pumps in this series provide reliable performance with low noise, robust and gentle fluid transfer by using vast cavities that can accommodate large solids. These pumps are optimized for energy-efficient operation.

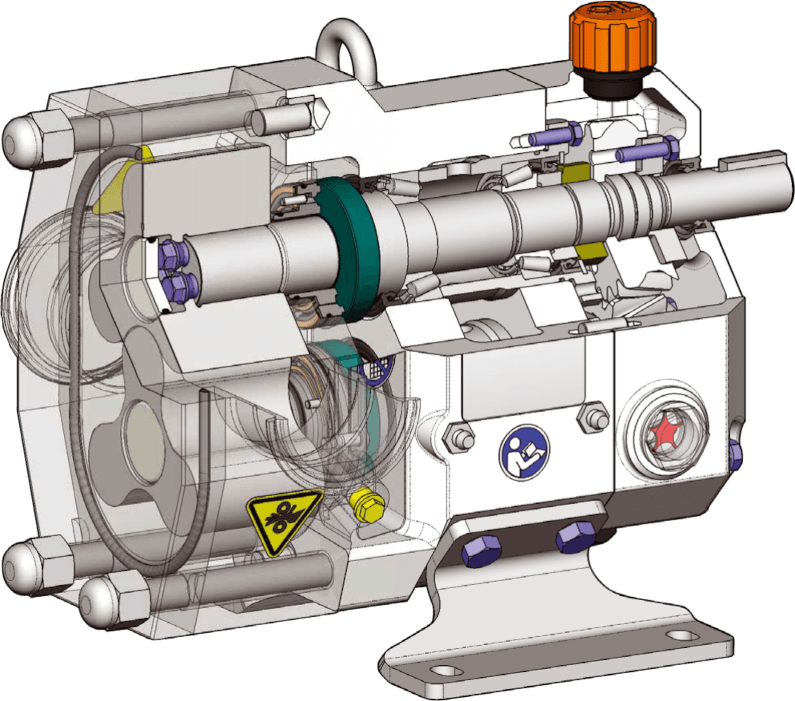

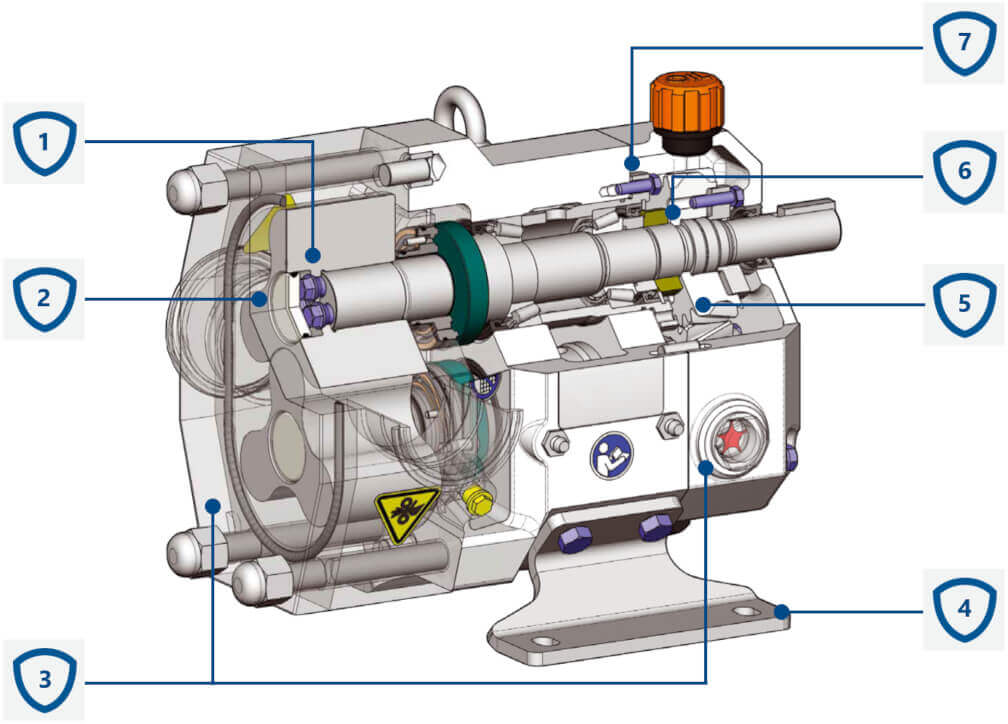

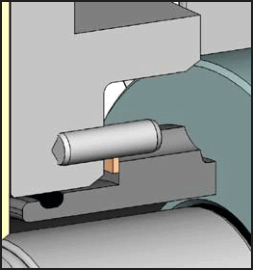

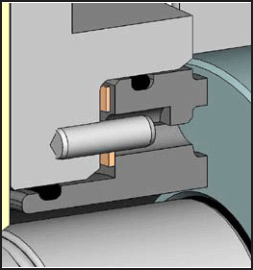

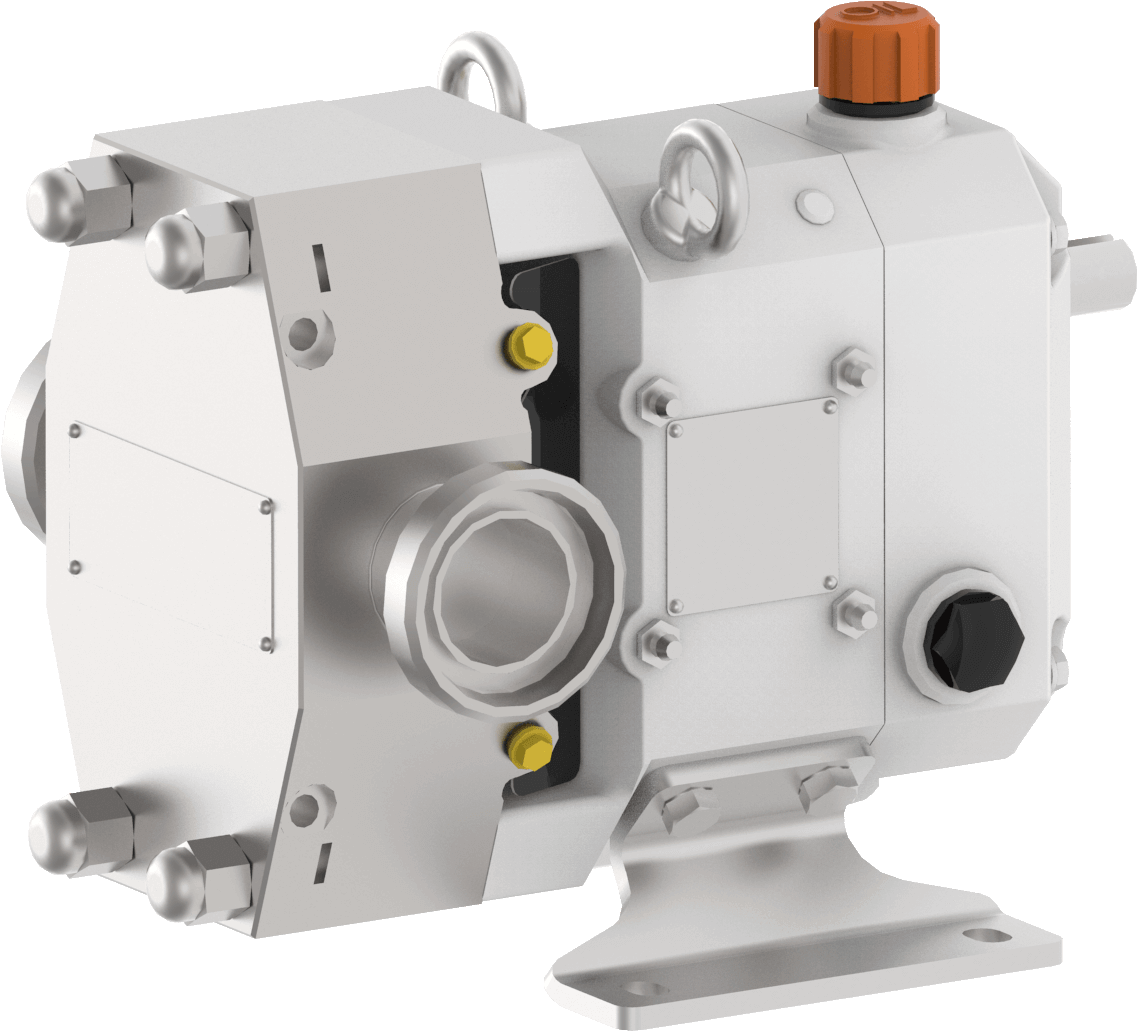

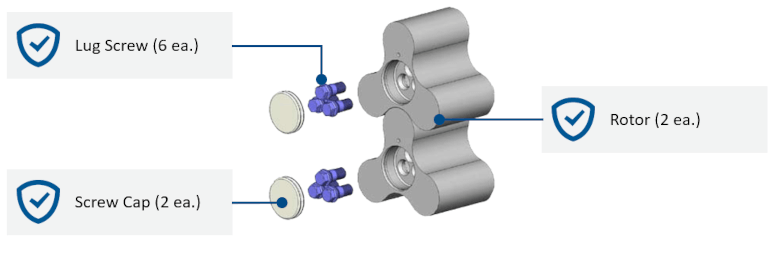

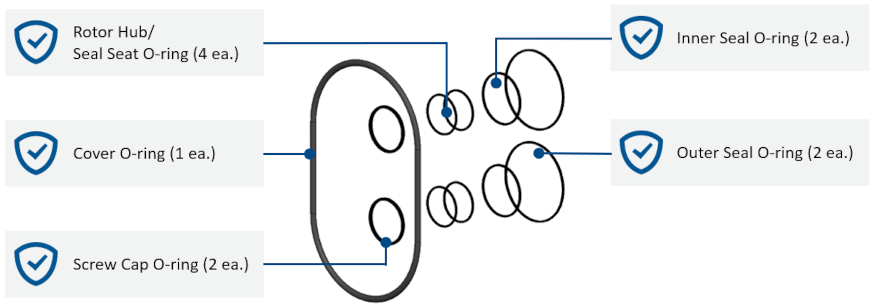

The design of the LPX series pumps features a special rotor-shaft mounting, ensuring accurate rotor positioning and a backlash-free connection. The unique gear housing design ensures no cross-contamination of the pumped product with gear oils. The pre-loaded tapered roller bearings do not require shims. As an option, they can be equipped with double mechanical seals for dry running. LPX series pumps provide good access to parts with easy maintenance and installation.

Tapflo Lobe pumps have a hygienic design confirmed by 3A certification and can be cleaned and sterilized on site (CIP/SIP). They are designed for pumping liquids in beverage and food production facilities, as well as comparable applications in the chemical, pharmaceutical and healthcare industries.

FEATURES & BENEFITS

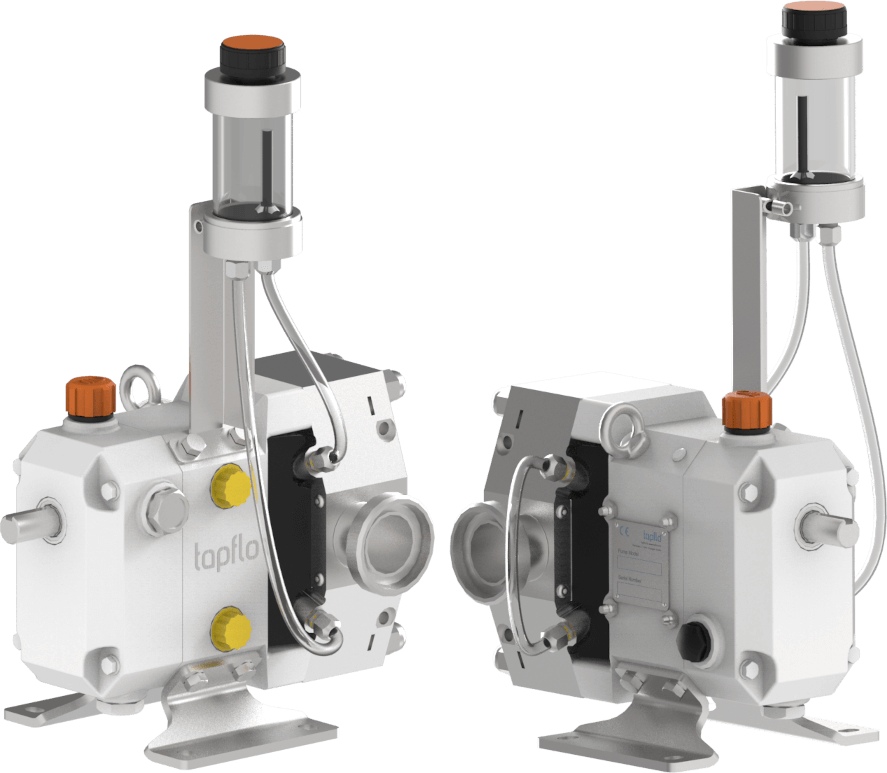

- Highest efficiency - energy conservation, low noise, low shear forces.

- Versatile design - 4-directional gear housing mounting. Possibility of bi-directional flow, as well as horizontal or vertical mounting.

- 8 sizes - a range of models with a maximum capacity of up to 82 m3/h and a pressure of 10 bar, allowing the pump to be tailored to specific customer requirements.

- Simple repair - easy to remove and install the pump body and cover.

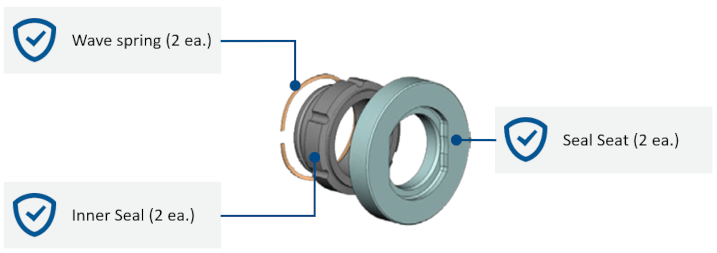

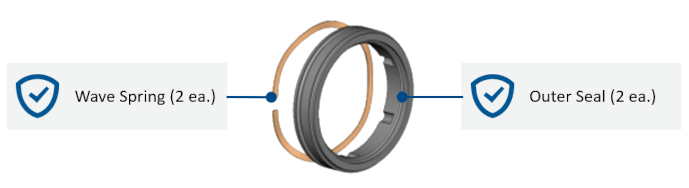

- Mechanical seal - single mechanical seal as standard. Double mechanical seals are also available as an option. Pumps with flush double mechanical seals can run continuously dry.

- Design with spacious cavities - large spaces between lobes enable gentle pumping of liquids with large solids.

- No cross-contamination - the gear oil is isolated from the pumped fluid zone due to the unique design of the gear housing.

- Suitable for CIP/SIP - design that allows cleaning and sterilization on site.

- Safety - the design of LPX pumps meets the requirements of hygienic standards 3-A and EHEDG, and is made of food contact materials approved by the FDA and EC Regulation 1935/2004.