TECHNICAL DATA

| Applications: | Liquids up to viscosity of 20.000 cP, also containing particles or powders. Appropriate for liquids stored in IBC tanks (IBC mixer) or drums (drum mixer) | |

| ATEX: | Available for potentially explosive atmospheres (ATEX zones) | |

| Rated voltage: | 400V AC, 50-60 Hz or 220-230V AC, 50-60 Hz | |

| Dimensions: | 1300x1200x3000 mm (lenght x width x height) | |

| Materials: | Wetted parts (impeller, shaft): AISI 316, PP, PFA, ECTFE. Other parts: AISI 304 or painted steel. |

|

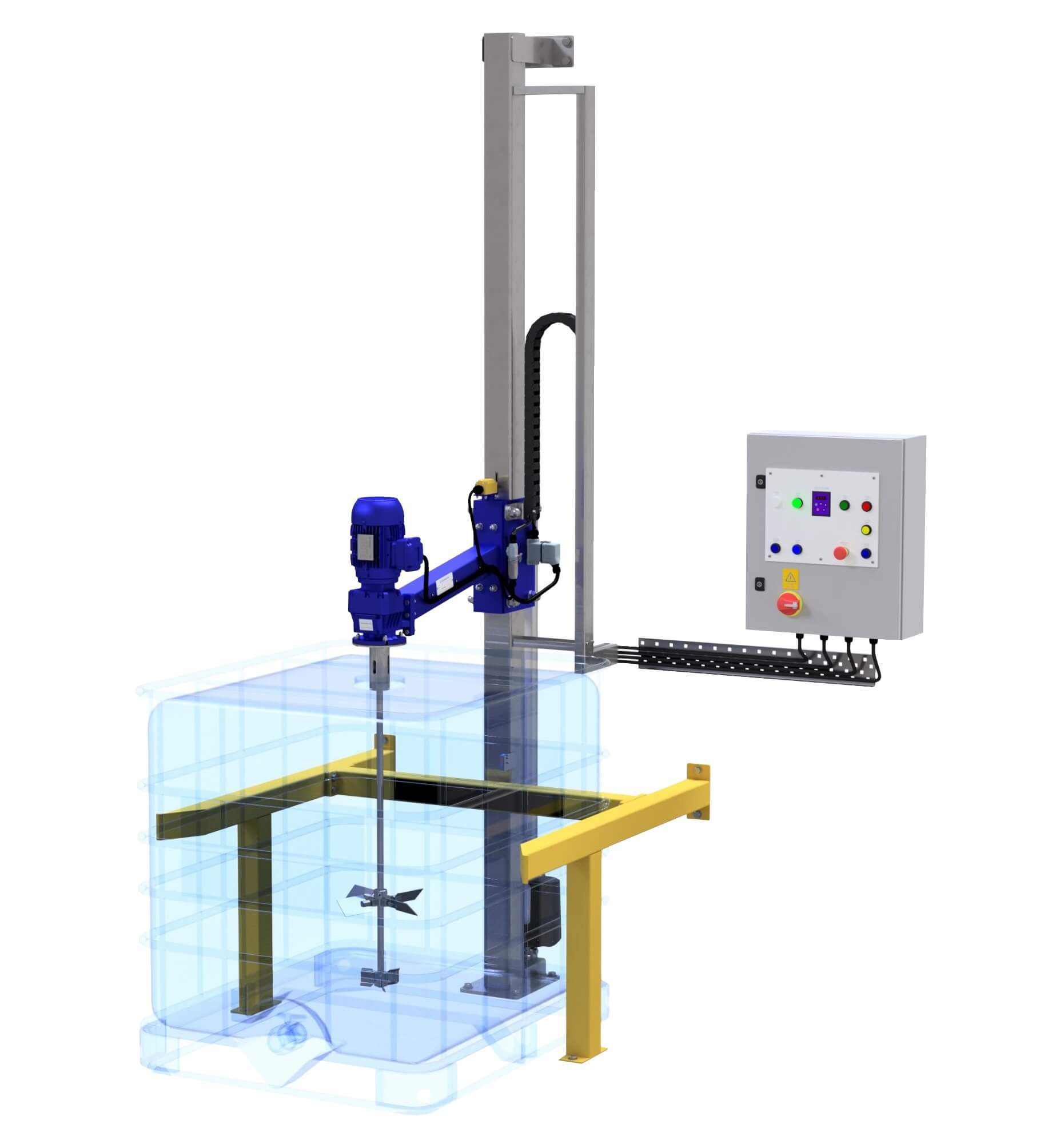

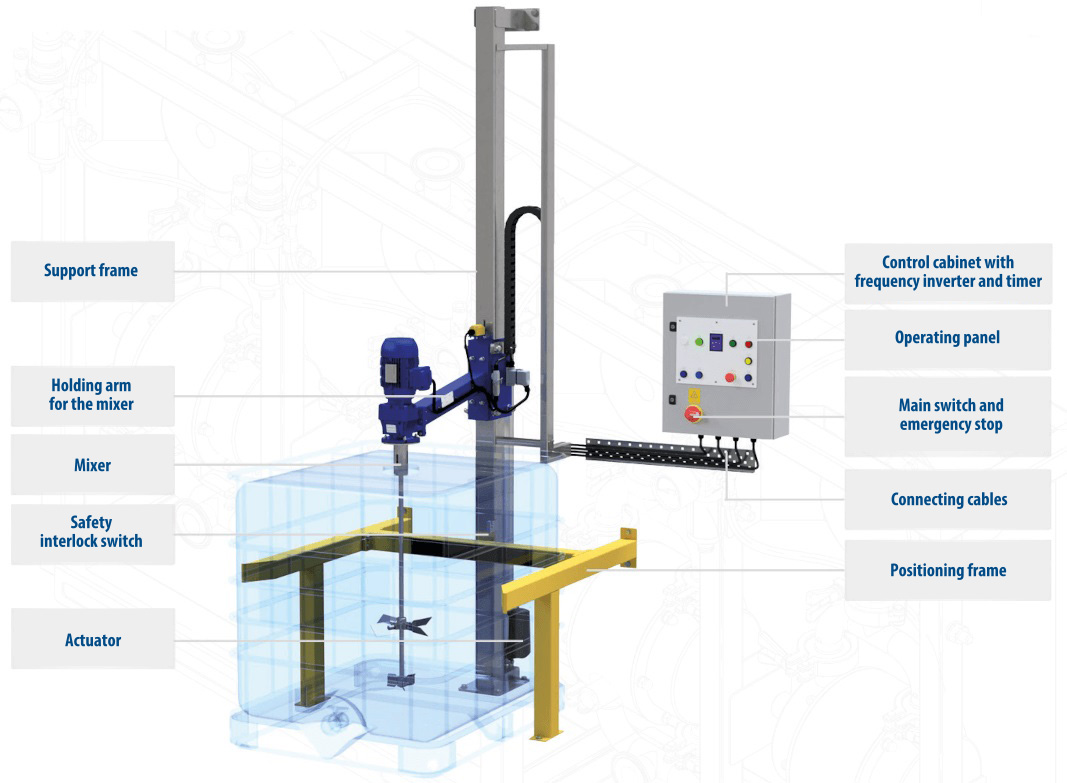

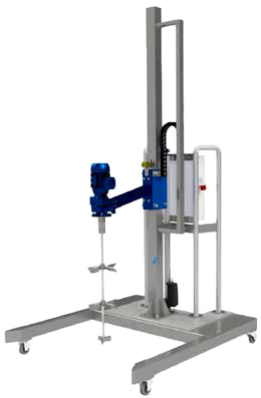

Save your time and use one, complete solution for mixing various liquid products. Mixing Station is an automated system for highly efficient mixing in an IBC. It is available both in stationary and mobile execution, allowing use in various locations.

Mixing stations are convenient and very easy to use. All operations are performed from the integrated control panel, which starts and stops the unit while also adjusting the speed of rotation. The only manual work to be done is the delivery of the IBC, and collecting it when mixing time is finished. Such a design allows for swift positioning and lowering of the mixer as well as setting the mixing timer.

IBC station guarantees a high level of safety – not only will the mixer not turn on while it’s raised above the container’s level, but also when the container is placed incorrectly or missing. While operating all the rotating elements are in an enclosed space removing the possibility of accidental, direct contact.

The shafts and impellers are available in a range of materials (AISI 316, PP, PFA, ECTFE). The operator, via a frequency inverter, can adjust the rotational speed of the mixer which allows it to be used for many different applications. IBC mixing station has been designed for mixing different liquids with each other or with powders ensuring their full dissolution in liquids.

FEATURES AND BENEFITS

- The mixer never runs without the IBC tank or in an incorrect position.

- Fully controlled via a control panel including the positioning of the electric actuator responsible for the height of the mixer.

- Adjustable mixing timer allowing for different jobs to be done in the meantime.

- Comes with guide rails for IBC tanks.

- Mobile or stationary installation.

- Adjustable mixing speed.

- Safe and reliable exploitation.

- Convenient and simple to use.

- High efficiency and better time management.

- Easy placement of an IBC tank.

- Safe and easy way to deliver the IBC tank with a hand pallet truck.

- Suitable for mixing different products of viscosity up to 20000 cP.

- Execution suitable for work in ATEX zones – according to ATEX directive, category II 2G.