DPT Pulsation dampener

The use of pulsation dampers in the discharge line guarantees a number of advantages, such as: significant reduction of discharge pulsations, vibrations and noise. This solution protects not only the pump, but also the piping and instrumentation.

More information here: Pulsation Dampeners

Revolution counter (RC)

The revolution counter allows to monitor the number of rotor revolutions.

This accessory can be equipped with a control cabinet. Based on the volume per revolution data, this allows to calculate and batch products according to customer needs.

Revolution counter can be also equipped with external digital display for easy monitoring of the pump speed and capacity.

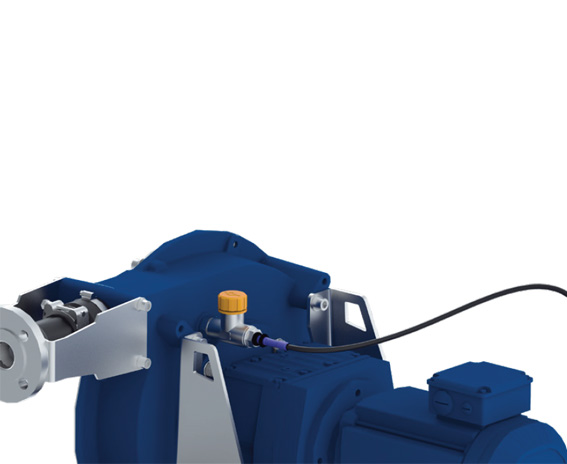

Hose leak detector (HLD)

The rupture of the hose, which is a wear part, creates a leakage of the pumped liquid.

As a result, the level of the medium in the pump casing rises and is detected by a capacitive sensor, which immediately stops the pump.

Vacuum system

The vacuum system is utilized in applications where viscous products are handled (above 10 000 cP) or with a negative suction lift.

Because of the liquid viscosity the hose does not return to initial shape fast enough and the capacity decreases.

By installing a vacuum system, efficiency drops are eliminated, as the pressure inside the pump is reduced and the hose is expanding quicker.

Build-in inverter (top or side)

Built-in frequency inverters are a solution for comfortable pump speed control. Allows easier exchange of the hose. The unit is equipped with a IP66 programmed frequency inverter and all necessary equipment such as wires and plugs.

The main advantage of this solution is that the inverter is mounted directly on the pump, which makes the whole unit compact and ready to use.

Trolleys

Trolleys are designed to enable mobility and ease of use, while maintaining proper pump stability.

Thanks to these new accessories, pumps can be easily transported and the most important, used in many applications and locations.