Technical data

| Model | Motor power KW |

IEC Motor size |

| CTI AA-03 | 0.37 | 71 |

| CTI AA-05 | 0.55 | 71 |

| CTI BB-07 | 0.75 | 80 |

| CTI CC-15 | 1.5 | 90 |

| CTI CC-22 | 2.2 | 90 |

| CTI CE-22 | 2.2 | 90 |

| CTI DD-40 | 4.0 | 112 |

| CTI DF-40 | 4.0 | 112 |

| CTI DF-60*** | 6.0 | 112 |

| CTI DG-60*** | 6.0 | 112 |

| CTI EF-55 | 5.5 | 132 |

| CTI EG-55 | 5.5 | 132 |

| CTI EF-75 | 7.5 | 132 |

| CTI EG-75 | 7.5 | 132 |

| CTI AA-024 | 0.25 | 71 |

| CTI BB-054 | 0.55 | 80 |

| CTI CC-114 | 1.1 | 90 |

| CTI CE-114 | 1.1 | 90 |

| CTI DD-224 | 2.2 | 100 |

| CTI DF-224 | 2.2 | 100 |

| CTI DG-224 | 2.2 | 100 |

*Special motor with increased power. Not available in EX-proof (ATEX) version

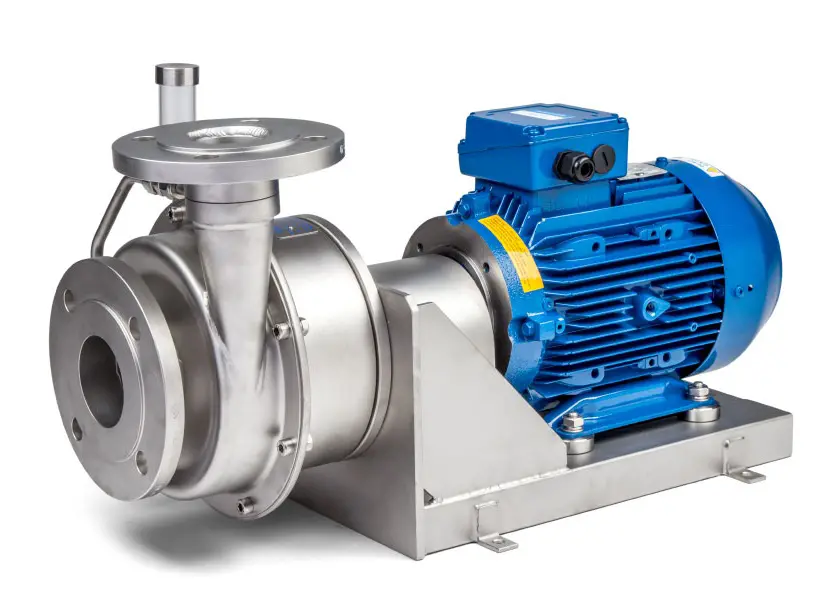

The CT pumps are open or semi open impeller single stage centrifugal pumps. They are manufactured in high finish and mechanically strong material - AISI 316L stainless steel. The pump range meets the demands from a variety of today’s industries. Having said that, CT is still available at a very appealing price level.

The industrial series CTI is designed with glass blasted pump casing. A variety of connection types, mechanical seal options and other executions are available to satisfy most industrial duties.

Features & Benefits

- Simple design

- Few parts

- Open impeller

- High grade materials

- Multiple options

- Compact design

- High capacity

- Competitive price

- Low maintenance cost

- Solids handling

- Good quality/cost ratio

- Wide range of applications

Typical APPLICATIONS

Chemical & pharma

Transport of chemicals from storage tanks, containers and baths, for example in degreasing. Handling of waste products.

Water treatment

Pumping samples, dosing acids and alkalis for pH-control. Transfer of flocculent, suspensions, chemical reagents and sludges. Pumps are resistant to even most agresive chemicals.